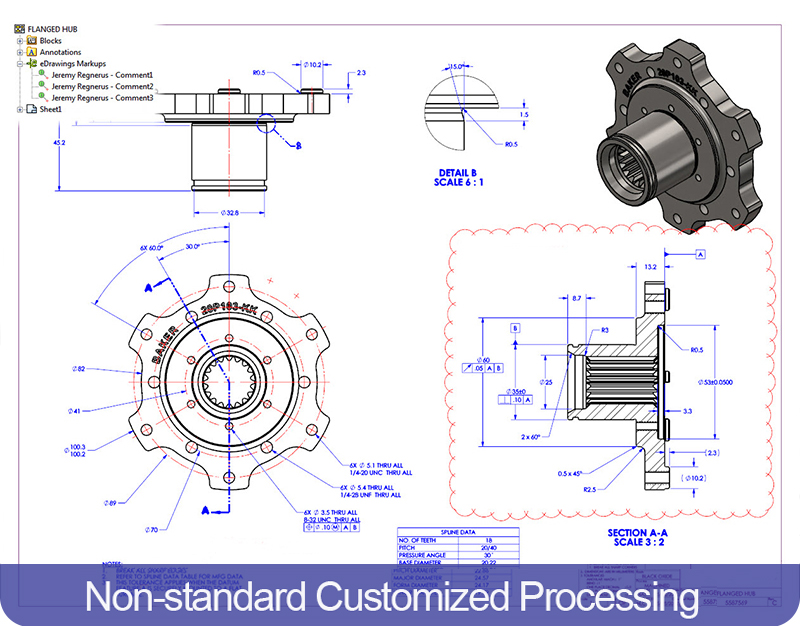

CNC Machining Metal Parts Service

Metal machining is a part manufacturing process that involves machining processes such as CNC machining, milling, turning, drilling, EDM and wire EDM etc, The part is cut to the desired shape, size and surface finish by a process of metal material removal to meet the specifications of product designs and engineering drawings.

We can provide implementation plans and technical support for the production of various mechanical metal projects.

Description

Machining Material:

Aluminum 6061/ 7075/ 2024/ 6063/ 6082/6060/ 5083;

Stainless Steel 303/304/ 316, Low Carbon Steel 1018, A36 Steel Plate; Brass, copper,titanium etc.

CNC Machining Process

| General Process Information | |||

| 3-Axis Milling | 5-Axis Milling | Turning | |

| MAX. Part Size | 1800*600*500mm | 8000*4000*2500mm | Ø350*600mm |

| MIN. Part Size | 12.7*12.7*12.7mm | 12.7*12.7*12.7mm | 6.4*6.4*6.4mm |

| MIN.Feature Size | Ø 1 mm | Ø 1 mm | Ø 1 mm |

| Standard Tolerance | +/-0.10-0.2mm’ | +/-0.04mm | +/-0.20mm |

| Lead Time | As low as 8days for less than 50 parts | As low as 10days for less than 50 parts | As low as 8days for less than 50 parts |

COMMON CNC MACHINING APPLICATIONS

CNC machining is often used to produce industrial parts in a subtractive manner from metal or plastic.

Tooling

Make complicated cuts at various angles.

![]()

Niche Manufacturing Processes

Cut durable metal products that alternative processes can’t create.

![]()

Low- to Medium-volume Production

Cost-effective for production runs in medium or small batches.

![]()

Metal Fabrication

Safe and effective way to meet the demand for high-quality metal parts with exceptional tight tolerance.

![]()