3D Printing SLA/SLS/SLM Service

3D printing is the process of making three-dimensional solid objects from digital files. 3D printing solutions include a range of rapid prototyping techniques that are fast and relatively cheap. From 3D design and printing to producing 3D model products, it only takes a few days, to bring more products to market faster.

3D Printing Applications:

1. Prototypes and parts with high levels of detail, used for concept visualization and models;

2. Validation prototyping, especially for large parts with smooth surfaces;

3. Master patterns for manufacturing technologies such as vacuum casting and reaction injection molding;

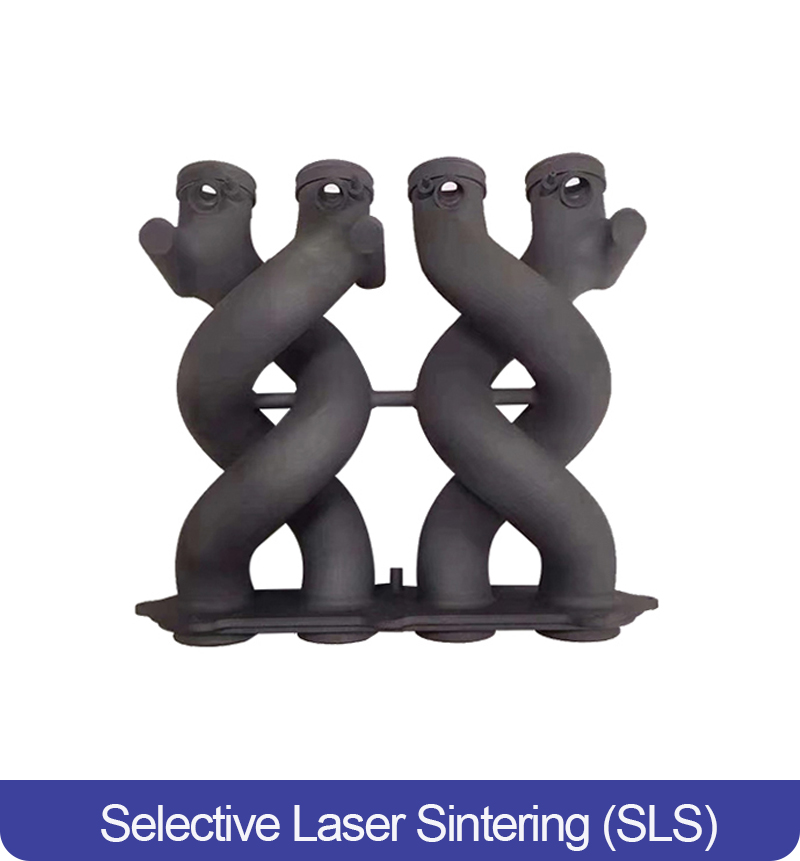

4. Low-volume manufacturing of models with complex geometries.

Why choose SEAL-RP 3D and design services

SEAL-RP is an experienced rapid prototyping service provider in China with 20 years of experience. We provide SLA printing service, SLS printing service, and SLM 3D printing service. As a professional prototype manufacturer, SEAL-RP has professional technical teams and advanced equipment, allowing SEAL-RP to provide customers with satisfactory 3D printing solutions in a short period. (1 set of CEMT SOUP II 600GS 600*600*500mm, 1 set of CMET RM 6000 600*600*500mm, 1 set of UNIONTECH RSPro 1400 1400*700*500mm, 2 sets of UNIONTECH RSPro 800 800*800*500mm, 15 sets of UNIONTECH RSPro 600 600*600*400mm, 10 sets of UNIONTECH RSPro 450 450*450*350mm).

Printing Material

SEAL-RP 3D printing materials include transparent/translucent resins, PA / PA+GF, white ABS resins, high toughness ABS resins and some metal materials (aluminum alloy, stainless steel, titanium alloy, die steel). SEAL-RP 3D printing technology can be applied to master molds, concept models, general parts and functional prototypes in the aerospace, automotive, medical and consumer electronics industries.

White ABS like Resin

Tolerance: ±0.1mm

Color: White

Heat deflection temperature: normal temperature

FEATURES:

• Easy to clean & finish

• High strength & durability

• Accurate & dimensionally stable

• Able to achieve precise details

• Good for general prototypes or aesthetic parts

High toughness ABS like Resin

Tolerance: ±0.1mm

Color: Yellowish Green

Heat deflection temperature: 65 ℃

FEATURES:

• Easy to clean & finish

• High strength & durability

• Accurate & dimensionally stable

• Able to achieve precise details

• Good for general prototypes or aesthetic parts

• Similar properties to ABS.

• Strength and Hardness are higher than white ABS like Resin.

Transparent Resin/Translucent Resin

Tolerance: ±0.1mm

Color: Transparent /translucent

Heat deflection temperature: normal temperature

FEATURES:

• High strength

• Perfect light transmittance property

• Accurate & dimensionally stable

• Able to make clear parts with intricate features

•Translucent resins can be polished to make them completely transparent

PA / PA+GF

Tolerance: ±0.1mm

Color: white /black

Heat deflection temperature: 120-140℃

FEATURES:

•High temperature resistance, High strength & durability

•Accurate & dimensionally stable

•Good mechanical properties,

•Ideal for applications requiring high stiffness.

•The surface is slightly granular and rough

Metal Material: Aluminium Alloy, stainless steel, titanium alloy and die steel

Tolerance: ±0.05mm

Color:natural

FEATURES:

•High temperature resistance, high strength, high precision

•The complex metal parts can be integrally formed with high processing precision and fast speed, which helps customers to complete the complicated design and manufacture easily.